Understanding the proper way to operate and maintain a powerful garden machine is crucial for achieving the best performance. This section offers detailed insights into essential procedures and recommendations that will help users make the most of their equipment. With a focus on both functionality and safety, this guide will walk through the necessary steps to ensure smooth operation and long-lasting efficiency.

Regular upkeep is key to extending the life of any heavy-duty device. We’ll cover fundamental maintenance practices, addressing key components that need attention for optimal results. Whether you’re new to operating this kind of machinery or looking to enhance your existing knowledge, these guidelines will provide the necessary tips to keep your device running smoothly.

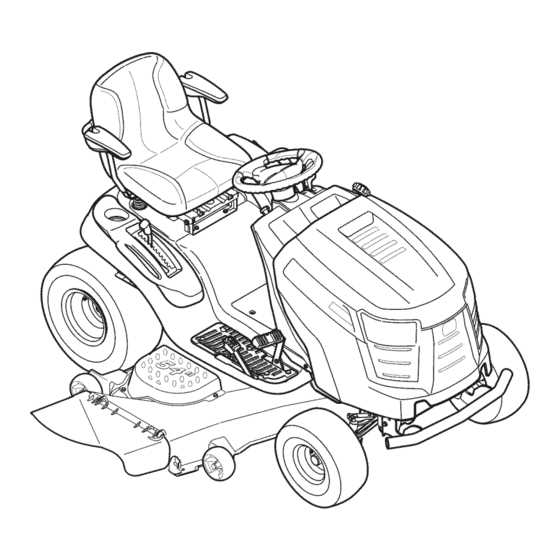

Maintenance Tips for Your Riding Mower

Proper care and regular upkeep are essential to ensure your lawn tractor remains in top working condition. By following a few simple maintenance routines, you can extend the machine’s lifespan and enhance its performance in cutting and handling various terrains.

Regular Engine Checks

To maintain optimal engine performance, it’s crucial to routinely inspect oil levels, change the oil, and check for any leaks. Ensuring the air filter is clean and replacing it when necessary will also improve the efficiency of the engine. A well-maintained engine will result in smoother operation and a more reliable start every time.

Blade Care and Cleaning

The cutting blades need to be kept sharp for a clean cut and to prevent strain on the engine. Regularly inspect and sharpen the blades, or replace them when dull or damaged. Additionally, keep the deck clean from debris buildup, which can affect the mower’s overall cutting efficiency.

Proper Care for Extended Lifespan

Regular maintenance and proper handling are key factors to ensure the longevity of your equipment. By dedicating time to routine care, you can significantly reduce wear and tear, ultimately extending the lifespan of your machine. This involves following specific guidelines to maintain its functionality and reliability over the long term.

Essential Maintenance Practices

To keep your machinery in peak condition, regular inspections are crucial. Make sure to check the oil levels, clean the filters, and ensure all moving parts are lubricated. These steps are fundamental for preventing mechanical failures and promoting consistent performance.

Handling and Storage Tips

Proper handling goes beyond just using the equipment correctly. After each use, clean the machine thoroughly to remove dirt and debris. When storing for extended periods, ensure it is in a dry and sheltered environment to avoid rust and corrosion, which can affect the internal components. Consistent upkeep will safeguard the equipment for years to come.

Essential Safety Practices to Follow

When working with powerful equipment, it is crucial to prioritize safety. Proper awareness of the environment, along with the use of the right protective gear, helps prevent accidents and ensures smooth operation. Familiarizing yourself with common safety protocols is an important step toward reducing risks.

Always inspect the machine before each use to make sure all components are functioning properly. Ensure that the surrounding area is clear of obstacles, and keep bystanders at a safe distance during operation. If something seems out of place or broken, it’s essential to stop and address the issue before proceeding.

Wearing appropriate protective clothing, such as gloves, safety goggles, and sturdy footwear, adds an additional layer of protection. Additionally, it’s important to be mindful of how you handle the machine, ensuring your posture and movements are stable to avoid strains or injuries.

Troubleshooting Common Performance Issues

Identifying and resolving performance challenges in your equipment is crucial for maintaining optimal functionality. Common problems often arise from wear and tear, improper use, or environmental conditions, but with the right approach, they can be quickly addressed.

Engine Power Loss

One of the most frequent issues involves a noticeable decrease in engine power. This can result from blockages in the air filter, fuel delivery problems, or insufficient lubrication. Regular maintenance, such as cleaning filters and checking oil levels, often prevents these complications.

Uneven Cutting

Another common issue is uneven cutting, which is usually caused by dull or improperly aligned blades. Sharpening the blades and ensuring they are properly balanced can significantly improve performance and deliver a more consistent result.