This section provides valuable insights and instructions aimed at enhancing the experience of users interacting with their agricultural machinery. Understanding the operational nuances and maintenance protocols can significantly impact efficiency and performance.

Within this guide, essential information will be outlined, including specifications, maintenance routines, and troubleshooting tips. The objective is to empower individuals with the knowledge required to optimize functionality and ensure longevity.

By familiarizing oneself with the intricacies of the equipment, operators can make informed decisions that lead to better productivity. This resource serves as a practical tool for anyone seeking to master their machinery and achieve optimal results in their tasks.

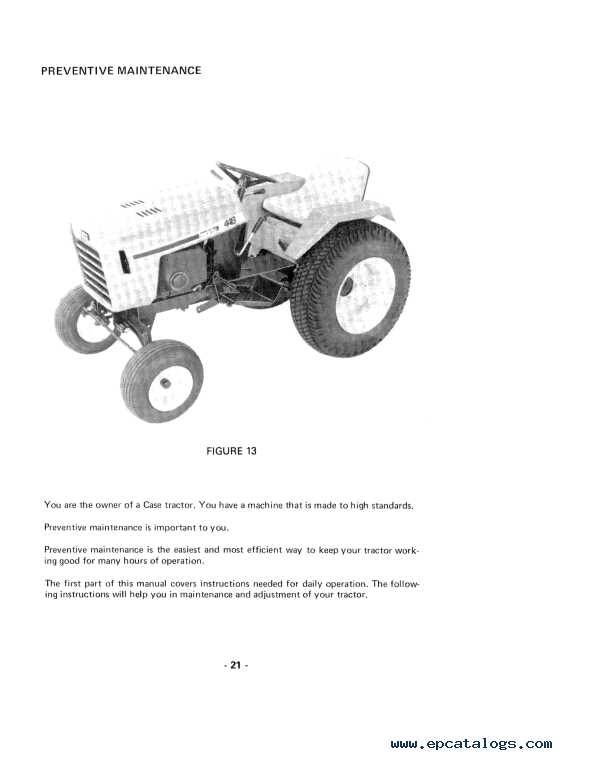

Understanding the Case 446 Features

This section delves into the distinctive characteristics and functionalities of the machine, highlighting how each aspect contributes to its overall performance and usability. By grasping these features, users can enhance their experience and optimize their work efficiency.

Performance Capabilities

The equipment is designed with advanced engineering to provide robust power and reliability. With a high-performance engine, it ensures efficient operation across various tasks, making it suitable for both light and heavy-duty applications. Users can expect consistent results, regardless of the complexity of the work involved.

User-Friendly Design

Ergonomics play a crucial role in the design of this machinery. The intuitive controls and layout facilitate ease of use, allowing operators to focus on their tasks without unnecessary distractions. Additionally, features like adjustable seating and enhanced visibility further improve comfort and operational effectiveness.

Maintenance is simplified through accessible components, ensuring that regular upkeep does not become a cumbersome chore. This focus on user-centric design ultimately leads to a more enjoyable and productive experience.

Maintenance Tips for Case 446

Proper upkeep of your equipment is essential for ensuring its longevity and optimal performance. Regular attention to various components can help prevent issues that may arise from neglect. Adopting a proactive approach will not only enhance efficiency but also reduce potential repair costs over time.

Begin with routine inspections to identify any signs of wear or damage. Pay close attention to fluid levels, filters, and belts, ensuring they are in good condition and replaced when necessary. Maintaining clean air and fuel filters will contribute significantly to engine performance.

Additionally, lubrication of moving parts is crucial. Regularly apply the appropriate grease or oil to joints and bearings to minimize friction and wear. Always refer to manufacturer specifications for recommended maintenance schedules and fluid types.

Finally, ensure that the battery and electrical systems are functioning correctly. Clean terminals and check connections to avoid power loss. Keeping your equipment in a clean and dry environment can also prevent rust and corrosion, further extending its service life.

Operating Guidelines for New Users

For those who have recently acquired a machine of this type, understanding its functionalities and operational nuances is essential for effective usage. Familiarity with key components, safety measures, and routine procedures can significantly enhance the user experience and ensure optimal performance.

Begin by reviewing the essential controls and features, which may vary depending on the model. It is crucial to become comfortable with the layout and functionality to operate the equipment efficiently. Pay attention to the safety instructions, as they are designed to protect both the user and the machine.

Before starting, conduct a thorough inspection of the equipment to ensure all parts are functioning correctly. Check fluid levels, and look for any visible signs of wear or damage. If any issues are detected, consult the troubleshooting section or seek assistance from a qualified technician.

When operating, maintain a steady pace and avoid sudden movements. Gradually adjust controls to become accustomed to the machine’s responsiveness. It’s advisable to practice in a safe environment until proficiency is achieved.

Lastly, keep a record of any maintenance performed and follow the recommended schedules for servicing. Regular upkeep is vital for prolonging the lifespan of the equipment and ensuring it operates at peak efficiency.