In the world of construction and woodworking, having a reliable pneumatic tool is essential for achieving professional results. These devices are designed to simplify tasks, improve efficiency, and ensure precision. For users of a specific model, familiarizing oneself with the essential features and operational guidelines can significantly enhance the overall experience and productivity.

Comprehending the intricacies of your equipment not only promotes safety but also extends the lifespan of the tool. Mastering its various functions allows for better handling and optimal performance, making your projects smoother and more enjoyable. Each tool comes with its unique set of characteristics and specifications, which can influence how you approach your work.

Exploring the documentation associated with your device will reveal crucial insights into its maintenance, troubleshooting, and best practices. Armed with this knowledge, you can tackle tasks confidently, knowing you are equipped to maximize the capabilities of your pneumatic helper.

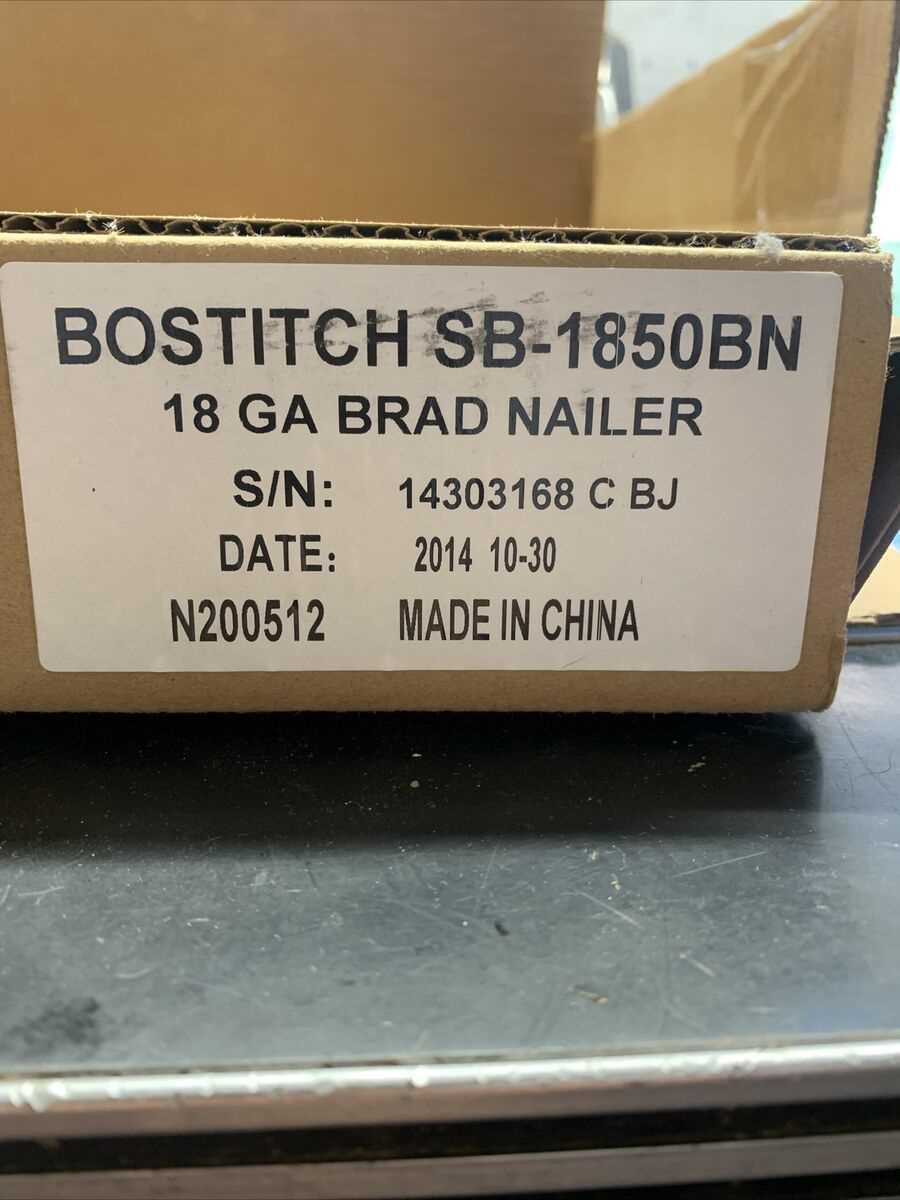

Bostitch SB1850BN Overview and Features

This section provides an in-depth look at a popular pneumatic fastening tool, highlighting its capabilities and essential characteristics that make it a preferred choice among professionals and DIY enthusiasts. The design is tailored for efficiency, ensuring optimal performance in various applications.

Key Features

This tool boasts a robust build, designed for durability and longevity. It features adjustable depth control for precise fastening, enhancing versatility across different materials. The quick-release nose mechanism simplifies jam clearing, ensuring minimal downtime during projects.

Performance and Usability

Equipped with a lightweight frame, this device offers ease of handling without compromising power. Its air-powered operation provides consistent driving force, making it suitable for a range of tasks from framing to finishing. The ergonomic grip enhances user comfort, allowing for extended use without fatigue.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your pneumatic tool operates efficiently and reliably over time. Proper maintenance not only extends the lifespan of the equipment but also enhances its overall performance, reducing the likelihood of unexpected issues during use.

- Keep It Clean: Regularly remove dust and debris from the tool to prevent buildup that can affect performance.

- Lubrication: Apply appropriate oil to the moving parts as recommended by the manufacturer to ensure smooth operation.

- Check Fasteners: Periodically inspect all screws and bolts to ensure they are tightened securely to avoid any operational problems.

- Inspect the Air Supply: Ensure that the air compressor is functioning properly and delivering the correct pressure levels to avoid any issues.

Additionally, consider implementing a routine check-up schedule to catch any potential problems before they escalate. Following these guidelines will help maintain peak efficiency and reliability for your tool.

- Establish a weekly cleaning routine.

- Change lubricants as per the specified intervals.

- Conduct a monthly performance check.

- Replace worn or damaged parts immediately.

By dedicating time to these practices, you can ensure that your tool remains in top condition, allowing you to achieve the best results in your projects.

Troubleshooting Common Issues with Bostitch

When working with pneumatic tools, encountering problems can be frustrating. This section aims to provide guidance on identifying and resolving frequent complications that users may face. Understanding the common issues can help maintain efficiency and prolong the lifespan of your equipment.

One prevalent issue is inconsistent firing, which may result from insufficient air pressure. Ensure that the compressor is set to the recommended PSI for optimal performance. Additionally, check for any leaks in the air hose or fittings that could be affecting power delivery.

Another common concern is jams. These often occur due to incorrect fasteners or buildup of debris. Regular cleaning of the tool and using the specified fasteners can significantly reduce the likelihood of jams. If a jam does occur, safely follow the manufacturer’s instructions to clear it without causing damage.

Lastly, if the tool is not operating smoothly, lubrication might be required. Regularly apply the recommended oil to the tool’s moving parts to ensure seamless operation and prevent wear and tear. Always refer to the specific guidelines for your device to maintain optimal performance.