Understanding the intricacies of your agricultural machine is crucial for optimal performance and longevity. This guide is designed to provide valuable insights and instructions for operators looking to enhance their experience with their equipment. Whether you are a seasoned farmer or a newcomer to the world of machinery, familiarizing yourself with key operational aspects will significantly benefit your productivity.

Within this document, you will discover vital information covering maintenance routines, troubleshooting techniques, and safety precautions. Each section is crafted to address common queries and concerns, ensuring that you are well-equipped to tackle any challenges that may arise. By adhering to these guidelines, you will not only improve the efficiency of your machinery but also extend its service life.

We encourage you to delve into the details provided here. By doing so, you will gain a deeper understanding of your equipment’s capabilities, which is essential for maximizing its potential on the field. Stay informed, stay proactive, and enjoy the rewarding experience of managing your agricultural tasks with confidence.

Understanding the 2018 John Deere 2025R

This section provides insights into a compact utility vehicle designed for versatility and efficiency. It combines power and functionality, making it suitable for various tasks, from landscaping to agricultural work.

Key Features

- Robust engine performance

- Compact size for maneuverability

- Multiple attachment options

- User-friendly controls

Maintenance Tips

- Regular oil changes to ensure engine longevity

- Check and replace filters as needed

- Inspect tires for wear and proper inflation

- Keep the exterior clean to prevent rust

Key Features and Specifications Overview

This section provides an insightful look into the essential characteristics and technical details of a versatile compact tractor. Designed for efficiency and ease of use, these machines cater to a variety of tasks, making them ideal for both agricultural and landscaping purposes.

Equipped with a robust engine, this model delivers impressive power while maintaining fuel efficiency. Its compact size allows for exceptional maneuverability in tight spaces, enhancing productivity in diverse environments. The hydraulic system is engineered for optimal performance, enabling seamless attachment changes and effective operation of implements.

The operator’s station is designed with comfort and functionality in mind, featuring adjustable seating and intuitive controls that enhance the user experience. Safety features are incorporated throughout the design to ensure secure operation, making it suitable for users of all experience levels.

With a range of available attachments, this machine adapts easily to various tasks, from mowing to tilling, providing versatility that meets the needs of any job. This comprehensive overview highlights the significance of reliable performance and user-friendly design in today’s compact tractor solutions.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring your equipment operates at peak efficiency. Following a structured maintenance routine can extend the lifespan of your machinery, improve functionality, and prevent costly repairs. Here are some practical tips to keep in mind.

- Check Fluids: Regularly inspect and top off fluids such as oil, coolant, and hydraulic fluid to prevent engine wear and overheating.

- Inspect Filters: Clean or replace air and fuel filters as needed to maintain airflow and fuel efficiency.

- Tire Maintenance: Ensure that tires are properly inflated and check for wear to enhance traction and stability.

- Battery Care: Keep terminals clean and check the charge regularly to avoid unexpected shutdowns.

In addition to these basics, consider the following advanced tips:

- Follow the recommended service intervals outlined in your equipment documentation.

- Utilize high-quality parts and fluids to ensure optimal performance and longevity.

- Store your machinery in a dry place to protect it from weather-related damage.

- Keep a maintenance log to track inspections, repairs, and parts replacements.

By implementing these maintenance strategies, you can significantly enhance the reliability and performance of your equipment.

Common Issues and Troubleshooting Guide

This section aims to address frequent challenges encountered by operators and provide effective solutions. Understanding these common problems can enhance your experience and ensure optimal performance of your equipment.

Engine Won’t Start: If the engine fails to ignite, check the battery charge and connections. Ensure the fuel system is functioning properly, and inspect the air filter for blockages.

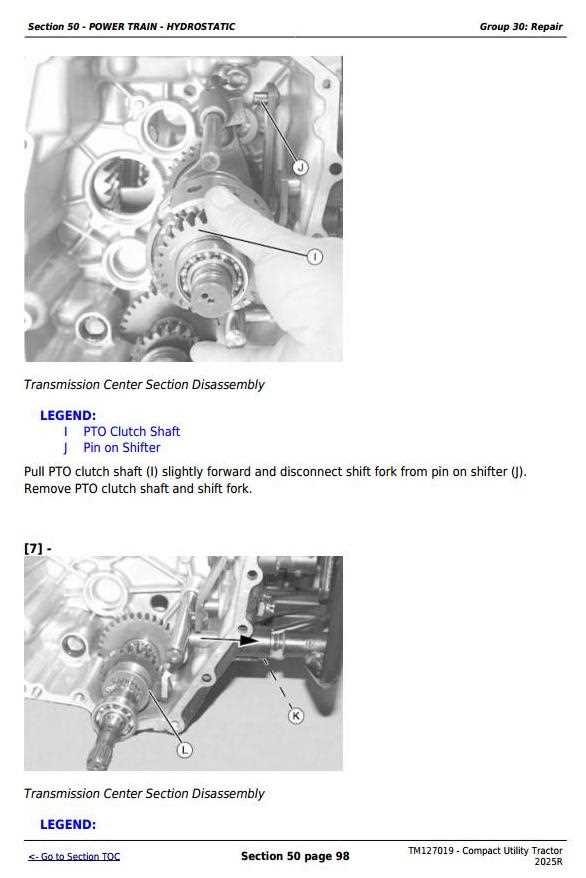

Hydraulic System Issues: Low hydraulic fluid levels can lead to decreased performance. Regularly check the fluid and replace it if necessary. Look for leaks around hoses and fittings.

Electrical Failures: If lights or other electrical components are malfunctioning, inspect the fuses and wiring for damage. A loose connection could also be the culprit.

Unusual Noises: Strange sounds may indicate mechanical wear or loose parts. Conduct a thorough inspection to identify and rectify the source of the noise.

Maintenance Tips: Regular maintenance is key to preventing issues. Follow the recommended schedule for oil changes, filter replacements, and overall inspections to keep your equipment running smoothly.