Compact utility vehicles offer a versatile solution for various tasks on small and mid-sized properties. Their ease of operation, durability, and multi-functionality make them indispensable for users who need a reliable machine for different types of jobs. Understanding the ins and outs of these vehicles ensures optimal performance and a longer lifespan.

In this guide, we’ll explore the essential aspects of maintaining and operating these machines efficiently. From basic setup to regular upkeep, each section provides clear and practical insights to help you get the most out of your equipment. Whether you’re using it for landscaping, light construction, or agricultural work, the key to success lies in proper care and knowledge.

With the right approach, you can enhance the functionality of your vehicle, reduce wear and tear, and ensure smooth operation across a wide range of tasks. Let’s dive into the essential tips and best practices to make the most of your utility vehicle.

Key Features of the 2018 John Deere 1025R

This versatile piece of equipment stands out for its practicality and efficiency, offering a blend of power, precision, and ease of use that makes it ideal for various tasks. Designed to perform well in different environments, it ensures both comfort and capability for operators.

One of the standout characteristics is its compact frame, which allows for excellent maneuverability. It’s perfect for tight spaces while still delivering robust performance. Additionally, the hydraulic system is engineered to provide smooth operation, ensuring that attachments can be changed quickly and effortlessly, saving valuable time on the job.

The model also boasts a user-friendly control system, designed with ergonomics in mind, ensuring that even prolonged use remains comfortable. Its durable build guarantees longevity, making it a reliable companion for years of service. Whether used for heavy-duty landscaping or light farm work, this machine

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure that your equipment runs smoothly and delivers peak performance over time. With a few consistent practices, you can extend the life of your machine and prevent costly repairs down the road.

Essential Maintenance Tasks

Here are some critical actions you should take to maintain your machinery in top condition:

- Check fluids regularly: Monitoring oil and hydraulic fluid levels helps to keep all components properly lubricated and functioning efficiently.

- Inspect belts and hoses: These should be checked for wear and cracks to avoid unexpected failures.

- Clean air filters: A clogged filter reduces airflow, leading to inefficiency. Make sure to clean or replace it as needed.

- Grease moving parts: Regular lubrication of joints and bearings can reduce friction and prolong the life of moving components.

Common Issues and Troubleshooting Solutions

Maintaining equipment in top condition is essential for long-term performance and efficiency. However, over time, various operational problems can arise, which may affect the functionality of your machinery. In this section, we’ll explore some of the most frequent issues users encounter and provide practical solutions for addressing them.

Engine Starting Problems

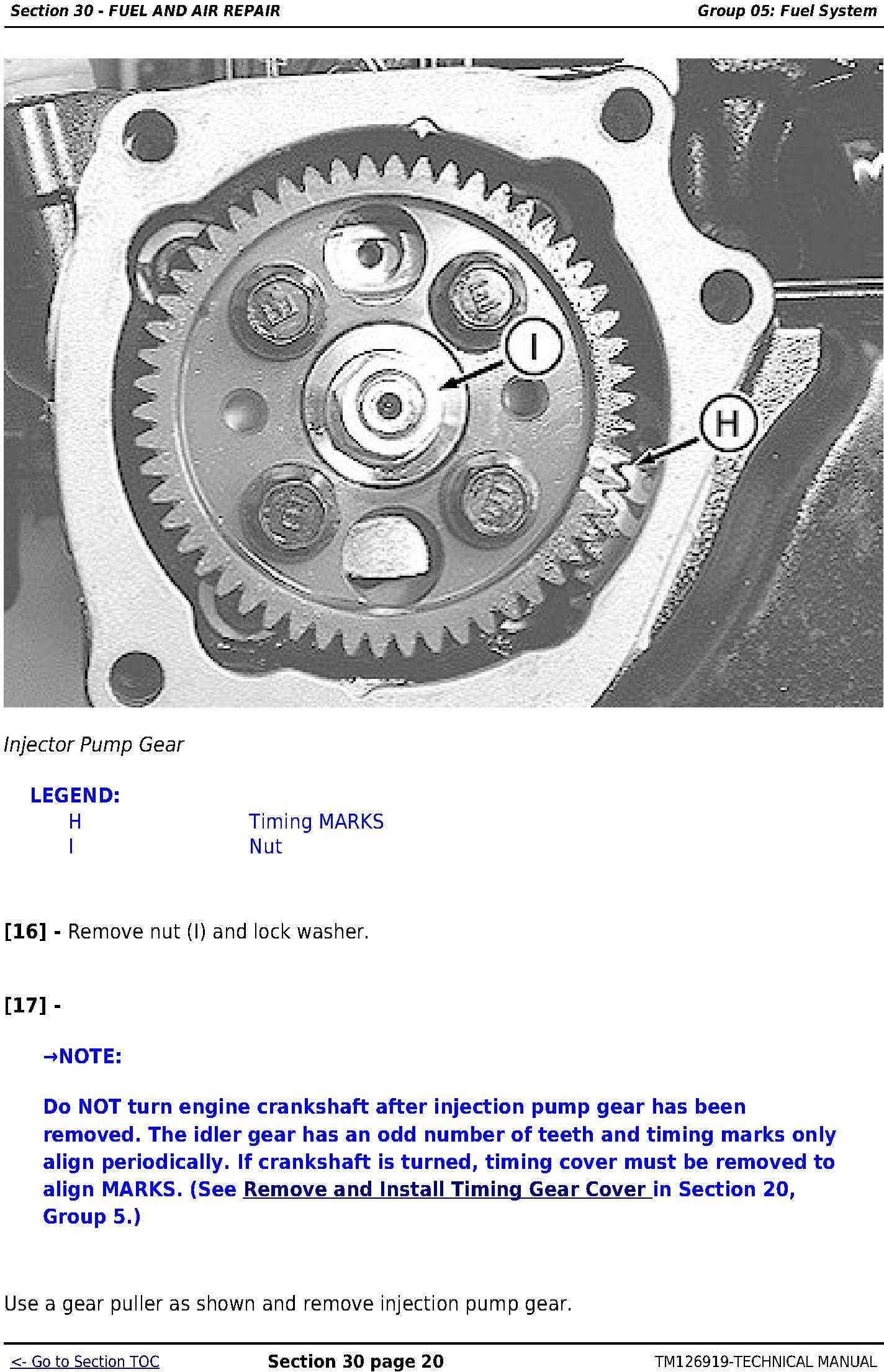

One of the common challenges involves the engine failing to start or experiencing delayed ignition. This can often be traced to battery-related concerns, such as poor connections or low charge. Check the battery terminals for corrosion and ensure they are securely attached. Additionally, verify that the fuel system is properly primed and that there is no blockage in the fuel lines.

Hydraulic System Malfunctions

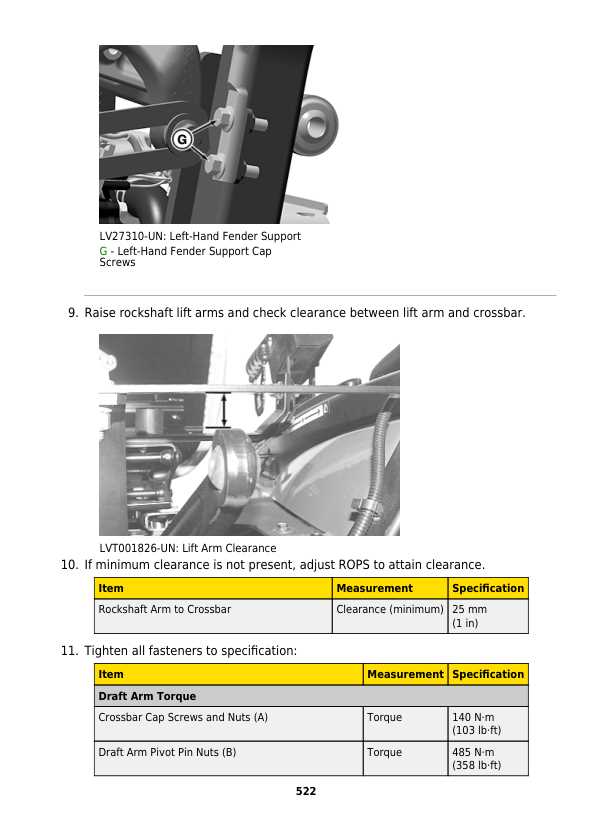

Hydraulic systems are critical for smooth operation, and malfunctions can lead to poor performance. Leaks or low fluid levels are frequent culprits. Inspect the hydraulic hoses for cracks or wear,