This guide serves as an essential resource for individuals seeking to enhance their understanding and proficiency with a specific compact track loader. With detailed insights and practical information, users can optimize their experience and ensure efficient operation.

Within this document, operators will find vital information regarding the machine’s features, maintenance practices, and operational guidelines. Each section is designed to assist users in mastering the various functionalities and maximizing the performance of their equipment.

By following the instructions and recommendations outlined in this guide, users can confidently navigate the challenges of operation and upkeep. A thorough understanding of the equipment not only promotes safety but also extends its lifespan, ensuring reliable performance throughout its use.

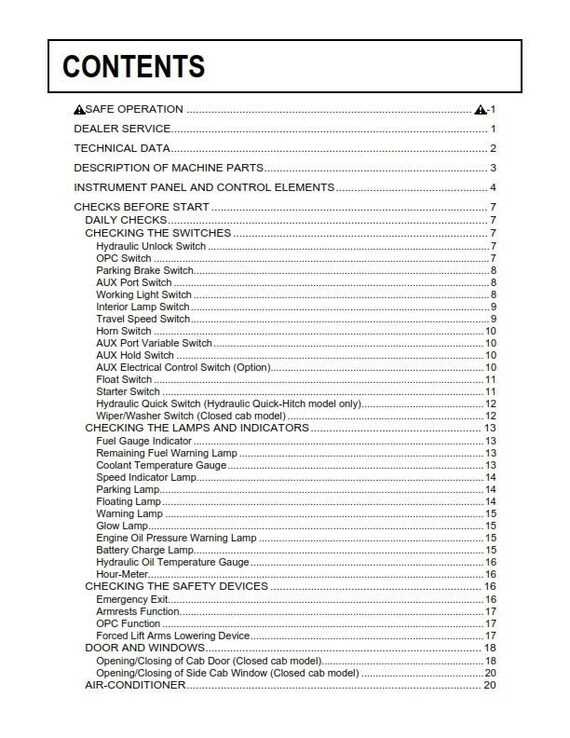

Features Overview

This section provides a comprehensive look at the key characteristics of a highly regarded compact track loader. Designed for versatility and efficiency, this machine is equipped to tackle a variety of tasks across different environments, making it an invaluable asset for operators in construction and landscaping.

One of the standout features of this model is its robust engine, delivering impressive power while maintaining fuel efficiency. This allows for extended operational periods without frequent refueling. The advanced hydraulic system enhances lifting capabilities, ensuring that heavy loads can be maneuvered with precision and ease.

Another notable aspect is the operator’s cabin, which has been engineered for comfort and usability. Ergonomic controls and ample visibility contribute to a safer working environment, reducing operator fatigue during long hours of use. Additionally, the inclusion of a spacious area allows for easy entry and exit, further enhancing the overall user experience.

Moreover, the machine’s compact design provides exceptional maneuverability, making it ideal for tight spaces where larger equipment cannot operate. Its durable construction ensures longevity and reliability, even in the most challenging conditions. These features collectively make this loader a preferred choice among professionals seeking a dependable and efficient solution for their heavy-duty tasks.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of machinery. Adhering to a structured maintenance plan can significantly enhance performance and prevent potential issues. Proper care not only maximizes productivity but also extends the operational lifespan of the equipment.

Below are key maintenance practices that should be incorporated into a routine schedule:

| Task | Frequency | Description |

|---|---|---|

| Fluid Levels Check | Daily | Inspect engine oil, coolant, and hydraulic fluid levels to ensure they are within recommended ranges. |

| Filter Replacement | Every 250 Hours | Replace air, oil, and fuel filters to maintain clean and efficient operation. |

| Greasing | Weekly | Apply lubricant to all moving parts to minimize friction and wear. |

| Visual Inspection | Monthly | Examine belts, hoses, and connections for signs of wear or damage. |

| Battery Maintenance | Every 6 Months | Check terminals for corrosion and ensure the battery is securely mounted and charged. |

Implementing these practices will significantly contribute to the smooth functioning of your equipment, helping to avert breakdowns and enhance overall performance. Make maintenance a priority to enjoy uninterrupted service and optimal results.

Common Issues and Troubleshooting Tips

When operating compact track loaders, users may encounter various challenges that can affect performance and efficiency. Understanding these common issues and how to address them can ensure smooth operation and prolong the machine’s lifespan.

Here are some frequent problems and corresponding troubleshooting strategies:

- Hydraulic System Malfunctions:

- Check for fluid leaks and ensure proper levels.

- Inspect hoses and fittings for wear or damage.

- Verify the operation of hydraulic controls and functions.

- Starting Difficulties:

- Ensure the battery is fully charged and connections are secure.

- Examine the ignition system for faults or corrosion.

- Check fuel levels and quality, replacing if necessary.

- Overheating:

- Inspect the cooling system for blockages or leaks.

- Ensure the radiator is clean and unobstructed.

- Monitor engine oil levels and replace if degraded.

- Track and Undercarriage Wear:

- Regularly inspect tracks for signs of damage or misalignment.

- Check tension and adjust as needed according to specifications.

- Examine rollers and idlers for excessive wear.

By being proactive and addressing these common concerns, operators can maintain optimal functionality and prevent costly repairs. Regular maintenance and attention to detail are key in ensuring longevity and reliability of the equipment.