When it comes to maintaining your agricultural equipment, having a comprehensive resource is essential. This guide aims to provide valuable insights and practical advice to help you get the most out of your compact tractor.

Within these sections, you will discover critical information on operational procedures, maintenance tips, and troubleshooting techniques. Understanding these elements not only enhances performance but also prolongs the lifespan of your machine.

By exploring this resource, you can ensure that your equipment remains in optimal condition, allowing you to tackle various tasks with confidence and efficiency. Embrace the knowledge and empower yourself to achieve greater results.

Regular upkeep is essential for ensuring machinery operates at peak efficiency. By adhering to a structured maintenance schedule, users can prevent potential issues and enhance longevity.

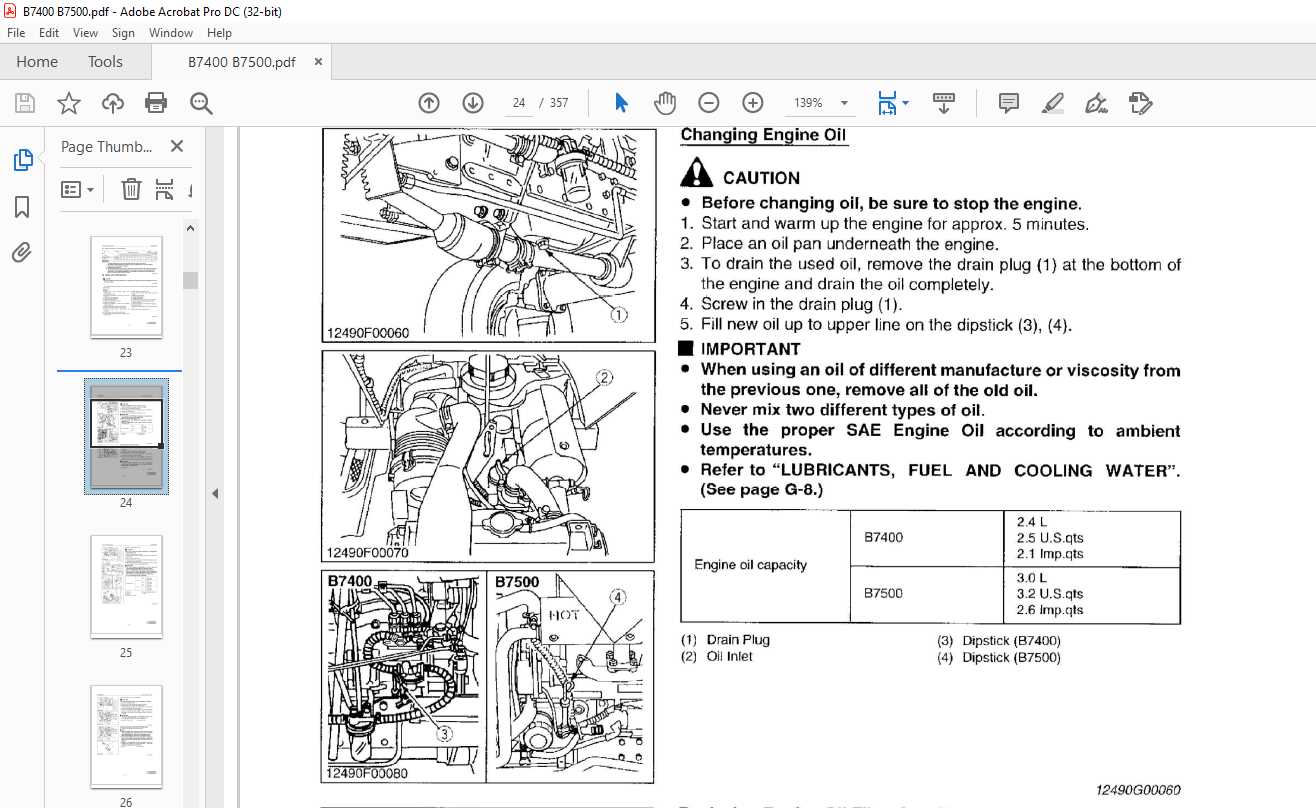

- Check fluid levels frequently, including engine oil, coolant, and hydraulic fluid.

- Inspect air filters and replace them as needed to maintain airflow and performance.

- Sharpen blades and replace worn-out components to ensure effective operation.

Additionally, it is advisable to:

- Conduct a thorough cleaning after each use to remove dirt and debris.

- Schedule periodic professional inspections to identify any underlying problems.

- Follow the manufacturer’s recommendations for any specific maintenance tasks.

By following these guidelines, users can achieve optimal performance and reliability from their equipment.

Common Troubleshooting Techniques Explained

Troubleshooting is an essential skill for any equipment owner, enabling quick identification and resolution of common issues. By applying systematic approaches, users can effectively diagnose problems and minimize downtime.

- Visual Inspection: Always start with a thorough examination of the equipment. Look for visible signs of wear, leaks, or loose components.

- Check Fluid Levels: Ensure that all necessary fluids, such as oil and coolant, are at appropriate levels to avoid performance issues.

- Listen for Unusual Sounds: Pay attention to any strange noises that may indicate mechanical problems, such as grinding or rattling.

- Refer to Specifications: Consult the specifications or performance guidelines to confirm that the machine is operating within its designed parameters.

By implementing these strategies, users can streamline the troubleshooting process and enhance their equipment’s reliability.