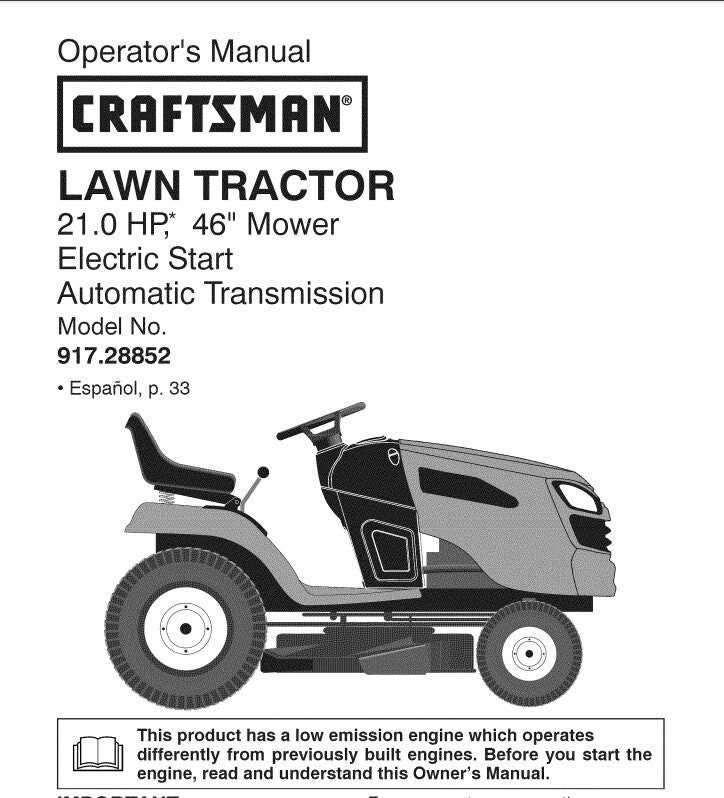

Having access to a comprehensive guide for your equipment can significantly enhance your experience as a user. This resource is designed to provide valuable insights into the features, maintenance, and operation of your device. With detailed instructions and helpful tips, you will be equipped to maximize its performance and longevity.

Whether you are a seasoned user or a newcomer, familiarizing yourself with the essential aspects of your machine is crucial. This document will walk you through various functionalities, troubleshooting techniques, and safety precautions, ensuring that you navigate any challenges effectively.

As you delve into the contents, you will discover a wealth of information tailored to assist you in making informed decisions. Embracing this knowledge empowers you to utilize your equipment to its fullest potential, ultimately leading to a more satisfying and productive experience.

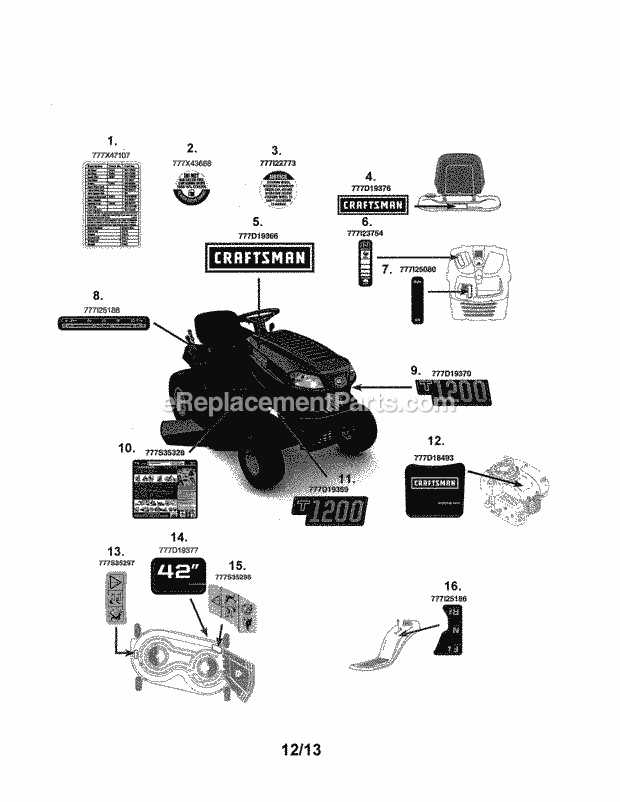

Understanding Your Craftsman T1200

This section aims to provide insights into the features and functionalities of your equipment. By familiarizing yourself with its components and operation, you can enhance your overall experience and ensure optimal performance.

Key Features

Familiarity with the main attributes of your device can significantly impact its efficiency. Here are some essential features that contribute to its versatility:

| Feature | Description |

|---|---|

| Durability | Built with high-quality materials for long-lasting use. |

| Ease of Use | Designed for straightforward operation, making it accessible for all users. |

| Maintenance | Features that simplify upkeep and prolong lifespan. |

Operating Guidelines

To maximize your device’s performance, understanding the basic operating guidelines is essential. Proper handling and adherence to recommended practices will help avoid potential issues:

- Always consult the provided guidelines before use.

- Ensure regular inspections to maintain functionality.

- Follow safety precautions to prevent accidents.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for ensuring that your equipment remains in excellent condition over the years. By following a few fundamental practices, you can significantly enhance its performance and extend its lifespan. Regular attention to maintenance tasks not only prevents breakdowns but also contributes to efficient operation.

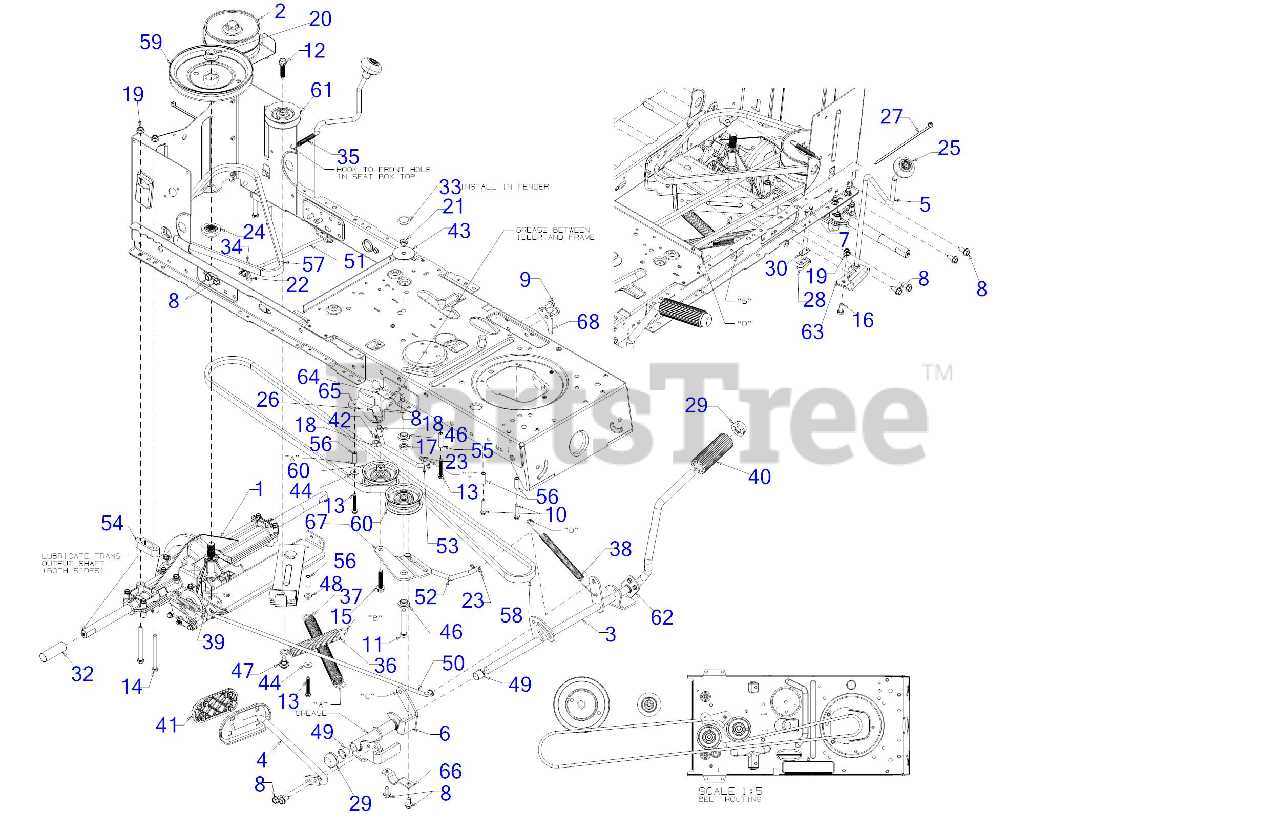

Regular Inspections

Conducting routine checks is essential. Look for any signs of wear or damage, which can help you address issues before they escalate. Inspect components such as belts, filters, and fluid levels to ensure everything is functioning optimally.

Cleaning and Lubrication

Keeping the unit clean and well-lubricated is vital. Remove debris and dirt that may accumulate over time, as this can hinder performance. Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Look for signs of wear and tear. |

| Clean Components | Monthly | Remove dirt and debris. |

| Lubricate Moving Parts | Every 3 Months | Use manufacturer-recommended lubricant. |

| Check Fluid Levels | Monthly | Ensure proper levels are maintained. |

Common Issues and Troubleshooting Guide

When operating a machine, users may encounter various challenges that can hinder performance. This section provides insights into typical problems and practical solutions to enhance functionality and user experience.

1. Difficulty Starting: One of the most frequent complaints is the inability to initiate operation. Ensure that the power source is connected and functioning. Check the battery or fuel levels, and inspect the ignition components for wear.

2. Uneven Performance: If the device exhibits inconsistent behavior, consider examining the settings and adjustments. Clean or replace any filters, as dirt accumulation can disrupt normal function.

3. Excessive Noise: Unusual sounds may indicate underlying mechanical issues. Tighten loose parts and lubricate moving components to mitigate this problem. If the noise persists, consult a professional for further evaluation.

4. Overheating: Machines can overheat during prolonged use. Ensure adequate ventilation and allow the unit to cool down periodically. Check for blockages in cooling vents and clean as necessary.

5. Electrical Problems: Flickering lights or loss of power can be attributed to electrical issues. Inspect wiring for damage, and verify connections to ensure they are secure. Replacing faulty fuses may also resolve this concern.

By following this guide, users can effectively address common difficulties and maintain optimal operation of their equipment.