Owning a piece of lawn equipment is an investment that requires proper understanding and care to ensure longevity and optimal performance. This section serves as a comprehensive resource for users, detailing essential information and operational instructions to help navigate the features of your machine effectively. Whether you are a novice or an experienced operator, grasping the fundamental aspects of maintenance can significantly enhance your experience.

Familiarizing yourself with the specifications and recommended practices is crucial for maximizing the functionality of your equipment. This guide encompasses various topics, including safety measures, troubleshooting tips, and regular upkeep procedures. By adhering to these guidelines, you can ensure that your machinery operates smoothly and efficiently, providing excellent results for your lawn care needs.

As you explore this material, you will uncover valuable insights that will aid in the responsible management of your tools. Understanding the intricacies of your device not only promotes safety but also empowers you to tackle common challenges with confidence. Equip yourself with the knowledge that will keep your equipment running at its best for years to come.

Understanding Your Craftsman T110 Features

This section provides an overview of the various attributes and functionalities available in your equipment. Recognizing these features can enhance your overall experience and ensure that you maximize the utility of your machine.

One key aspect to consider is the engine performance, which plays a crucial role in determining how effectively the equipment operates. Additionally, the ease of use and intuitive controls allow for a seamless operation, making it accessible for both novices and experienced users alike.

Another important feature is the durability of the components, designed to withstand rigorous tasks while providing reliability over time. Coupled with maintenance considerations, understanding these elements contributes to a more efficient and enjoyable usage.

Moreover, the design aspects, such as the ergonomic layout and user-friendly interface, significantly impact comfort and operational efficiency. Embracing these characteristics ensures that you are well-equipped to tackle various projects effectively.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the prolonged functionality and performance of any equipment. By adhering to a few key practices, users can significantly enhance the lifespan of their machines and minimize the need for repairs or replacements. Consistent care not only protects the investment but also ensures optimal performance throughout its use.

Regular Cleaning

Cleaning is a fundamental aspect of maintenance that should not be overlooked. Dust and debris can accumulate, potentially leading to operational issues. Make it a habit to clean surfaces regularly, ensuring that any moving parts remain unobstructed. Utilize a soft cloth and appropriate cleaning solutions to avoid damaging sensitive components.

Scheduled Inspections

Conducting inspections on a routine basis is crucial for early detection of any potential problems. Check for signs of wear and tear, including loose components or abnormal noises during operation. Addressing minor issues promptly can prevent more significant problems from developing, thus prolonging the lifespan of the equipment.

Common Issues and Troubleshooting Guide

This section provides insights into frequent challenges encountered by users and offers practical solutions. Understanding typical problems can significantly enhance your experience and extend the longevity of your equipment.

Engine Won’t Start: If the engine fails to ignite, ensure that the fuel tank is filled with fresh fuel and that the spark plug is clean and properly connected. A faulty ignition switch may also be a culprit.

Uneven Cutting: When your equipment cuts unevenly, check the blade for damage or dullness. Adjusting the cutting height and ensuring the wheels are properly inflated can also improve performance.

Excessive Vibration: Excessive vibrations may indicate that the blades are unbalanced. Inspect and tighten all bolts and screws, and ensure that the tires are inflated to the recommended pressure.

Stalling: Frequent stalling during operation can be caused by a clogged fuel filter or air filter. Cleaning or replacing these components often resolves the issue.

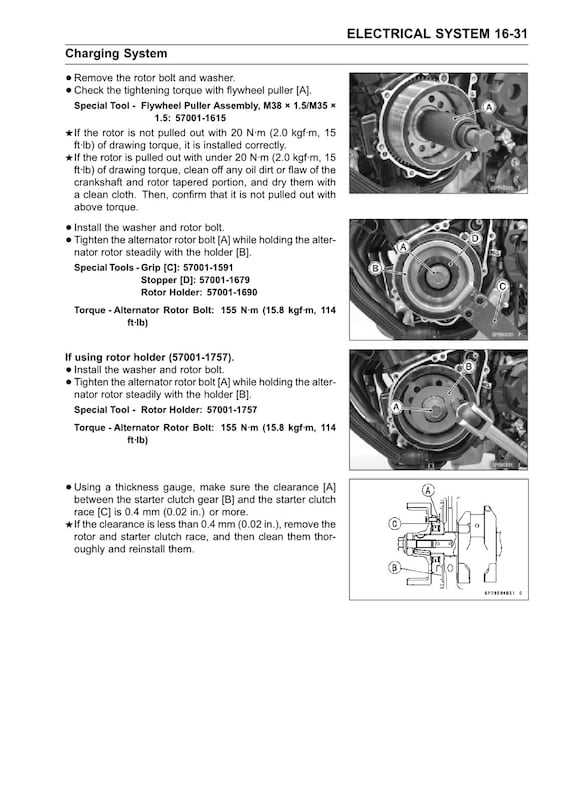

Electrical Issues: If you experience problems with the electrical system, check the battery connections for corrosion and ensure that the fuse is intact. Replacing a blown fuse can often restore functionality.

Maintenance Tips: Regular maintenance, including oil changes, cleaning air filters, and sharpening blades, can prevent many common problems and keep your equipment running smoothly.