In the world of compact machinery, understanding the functionalities and proper care of your equipment is essential for optimal performance. This guide serves as a comprehensive resource for users, providing valuable insights into the operation and upkeep of their machines.

Every piece of equipment comes with its own set of features and requirements, tailored to enhance productivity and longevity. Users will find detailed instructions that cover a wide range of topics, ensuring a thorough understanding of how to maximize efficiency while minimizing potential issues.

Additionally, this resource emphasizes the importance of regular maintenance, which plays a critical role in preserving the functionality and reliability of your machinery. By adhering to the guidelines presented, users can achieve seamless operation and extend the lifespan of their equipment.

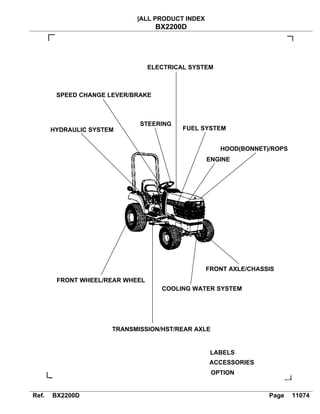

Kubota BX2200 Overview and Features

This compact utility vehicle is designed for a variety of tasks, offering versatility and efficiency for both residential and commercial use. With its robust engineering and user-friendly controls, it provides an excellent balance of power and maneuverability, making it suitable for various applications from landscaping to agricultural tasks.

Key Specifications

The machine is equipped with a powerful engine that ensures reliable performance while maintaining fuel efficiency. Its compact size allows for easy navigation in tight spaces, making it ideal for smaller properties or intricate job sites. Additionally, the hydraulic system enhances its capabilities, enabling efficient operation of attachments and implements.

Distinctive Features

Among its notable attributes, the ergonomic design promotes operator comfort during extended use. The intuitive dashboard provides essential information at a glance, allowing users to monitor performance effortlessly. Furthermore, its compatibility with a range of attachments extends functionality, enabling users to tackle diverse tasks with ease.

In summary, this compact vehicle combines power, efficiency, and versatility, making it a valuable addition to any toolkit.

Maintenance Tips for BX2200 Owners

Regular upkeep is essential for ensuring the longevity and optimal performance of your compact tractor. Implementing a structured maintenance routine can prevent costly repairs and enhance the machine’s efficiency. Here are some essential practices to follow.

- Check Fluid Levels: Regularly inspect and top off all fluids, including engine oil, hydraulic fluid, and coolant.

- Inspect Filters: Clean or replace air, fuel, and oil filters as needed to maintain engine health.

- Examine Tires: Ensure tires are properly inflated and check for wear or damage.

- Sharpen Blades: If your machine has cutting tools, keep them sharp for effective performance.

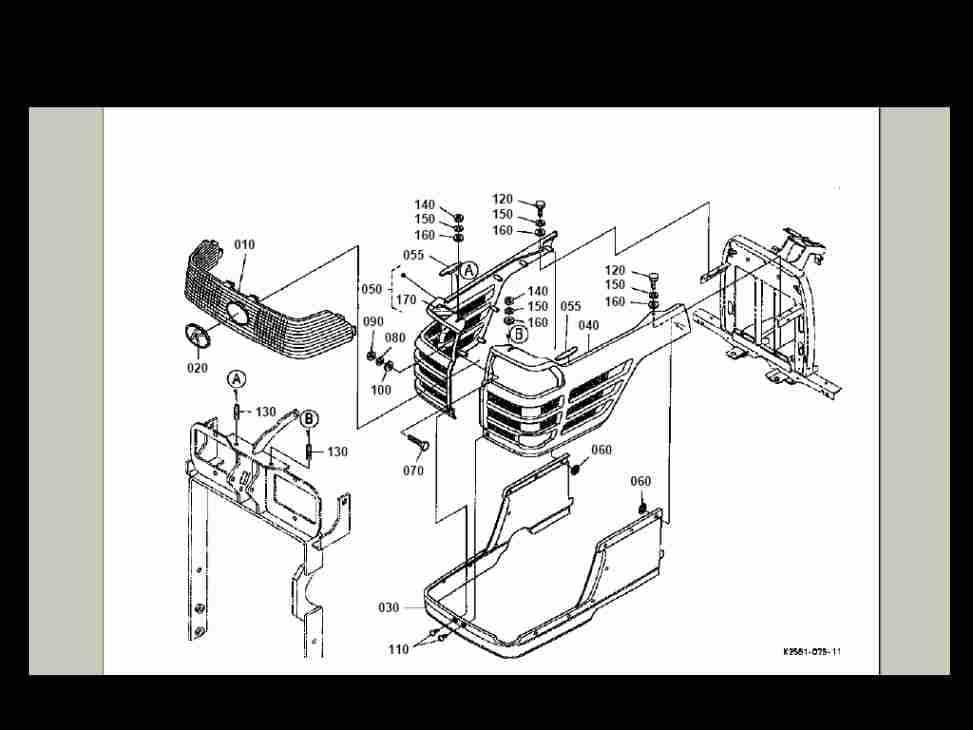

- Clean the Exterior: Regular cleaning helps prevent rust and buildup, preserving the machine’s appearance and functionality.

In addition to these tasks, consult the service guidelines for specific recommendations tailored to your model. Keeping a detailed log of maintenance activities can also help in tracking performance and identifying potential issues early.

Finally, consider seasonal preparations, such as winterizing procedures or summer checks, to ensure that your compact tractor is always ready for the tasks ahead.

Common Troubleshooting for Kubota BX2200

When operating compact tractors, encountering issues is not uncommon. Understanding the most frequent problems can help in quickly diagnosing and addressing them, ensuring smooth functionality and efficient performance. This section outlines typical troubleshooting techniques that can assist in maintaining optimal operation.

Engine Won’t Start

If the engine fails to ignite, check the battery connections first. Ensure that the terminals are clean and securely attached. If the battery is weak, a jump start may be necessary. Additionally, verify that the fuel tank has sufficient gasoline and that the fuel is not stale.

Overheating

Overheating can result from several factors. First, inspect the coolant levels and add more if needed. Check for any leaks in the cooling system. Cleaning the radiator and ensuring that the air intake is unobstructed can also help prevent excessive heat buildup.

Hydraulic Issues

If hydraulic functions are sluggish or unresponsive, check the hydraulic fluid levels. Low fluid can severely impair performance. Look for leaks in the hoses and connections. Additionally, ensure that the filters are clean to maintain proper fluid flow.

Unusual Noises

Strange sounds during operation can indicate mechanical problems. Listen for any grinding or clunking noises, which may signal issues with the transmission or other components. Regularly inspecting and lubricating moving parts can help mitigate these concerns.

By following these troubleshooting guidelines, users can effectively manage and resolve common issues, enhancing the longevity and efficiency of their machinery.