This section serves as a comprehensive resource for understanding and utilizing your equipment effectively. Whether you are a novice or an experienced user, having access to detailed information is essential for optimal performance and maintenance.

Within this guide, you will find crucial insights into operation, troubleshooting, and routine upkeep. Emphasizing clarity and practicality, the content is designed to enhance your experience and ensure that your machine functions smoothly.

By following the outlined procedures and recommendations, users can maximize their equipment’s potential. Embrace this opportunity to familiarize yourself with the features and best practices that will contribute to longevity and reliability.

Understanding Your Craftsman DLT 3000

This section aims to provide essential insights into the operation and maintenance of your equipment. Familiarizing yourself with its features and functionality will enhance your overall experience and ensure optimal performance.

Begin by exploring the various components that make up the machine. Understanding how each part interacts will help you troubleshoot issues more effectively. Regular checks and adjustments will contribute to longevity and reliability.

Additionally, knowing the recommended maintenance schedule is crucial. Routine care not only prevents potential malfunctions but also keeps your device running smoothly. Referencing the suggested practices will empower you to manage your equipment efficiently.

Key Features and Specifications Overview

This section highlights the essential characteristics and technical details of the equipment, providing users with a comprehensive understanding of its capabilities. Recognizing these features is crucial for optimal performance and effective usage.

Power and Performance: The machinery boasts a robust engine designed to deliver efficient power output, ensuring reliability in various tasks. Users can expect seamless operation even under demanding conditions.

Cutting Width: With a generous cutting width, this unit enhances productivity by covering more ground in a single pass. This feature is particularly beneficial for large areas, saving time and effort.

Transmission Type: Equipped with a sophisticated transmission system, the model offers smooth gear shifting, allowing for precise control and maneuverability on diverse terrains.

Comfort and Usability: Ergonomic design elements ensure that the operator enjoys a comfortable experience during prolonged use. Adjustable seating and intuitive controls contribute to ease of operation.

Safety Features: Safety mechanisms are integrated to protect the user, including automatic shut-off systems and secure braking functionalities. These aspects provide peace of mind while operating.

Maintenance and Durability: Constructed with high-quality materials, this model promises longevity and minimal maintenance requirements, making it an economical choice in the long run.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your equipment. By following a systematic approach to maintenance, you can significantly extend its lifespan and efficiency. This section highlights key practices that can help you keep your machinery in peak condition.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Every use | Ensure proper lubrication to avoid engine wear. |

| Inspect air filter | Monthly | Replace if clogged to maintain airflow. |

| Sharpen blades | Every season | Sharp blades ensure clean cuts and reduce strain. |

| Clean exterior | After each use | Remove dirt and debris to prevent corrosion. |

| Check tire pressure | Monthly | Maintain proper pressure for safe operation. |

Implementing these guidelines will not only enhance functionality but also contribute to the overall reliability of your machinery, making it a valuable asset for years to come.

Keeping Your Equipment in Top Shape

Maintaining machinery in excellent condition is essential for ensuring optimal performance and longevity. Regular upkeep not only enhances efficiency but also prevents unexpected breakdowns, allowing for a seamless working experience.

Regular Maintenance Tasks

- Check and replace air filters as needed to ensure proper airflow.

- Inspect and sharpen blades to achieve precise cutting.

- Clean any debris or buildup from the equipment’s exterior.

- Lubricate moving parts to reduce wear and tear.

Seasonal Preparations

- Before the onset of winter, drain fluids to prevent freezing.

- Store equipment in a dry, protected area to avoid rust and damage.

- Inspect belts and hoses for any signs of wear and replace if necessary.

By following these essential practices, you can ensure your tools remain reliable and efficient throughout their lifespan.

Troubleshooting Common Issues

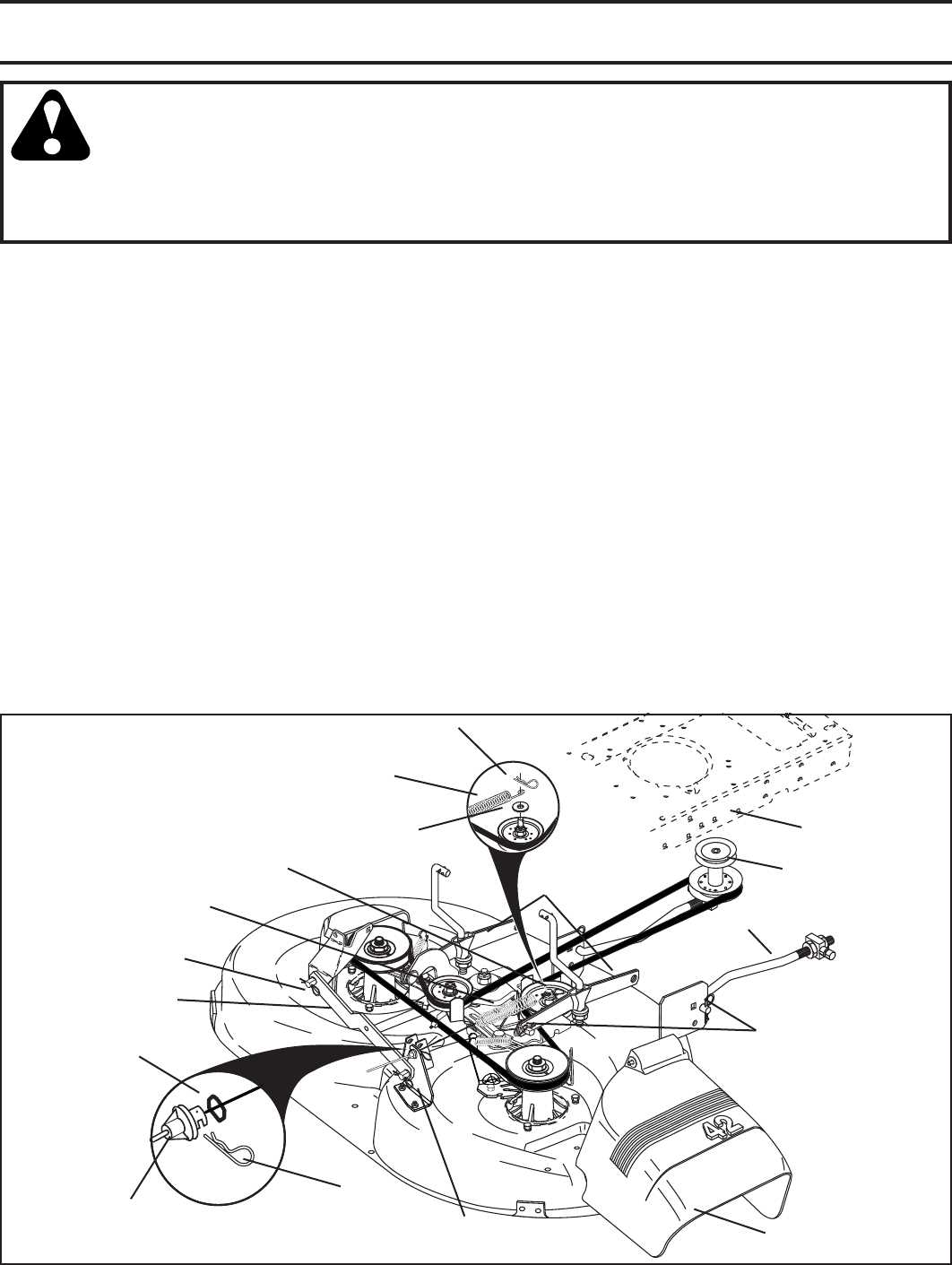

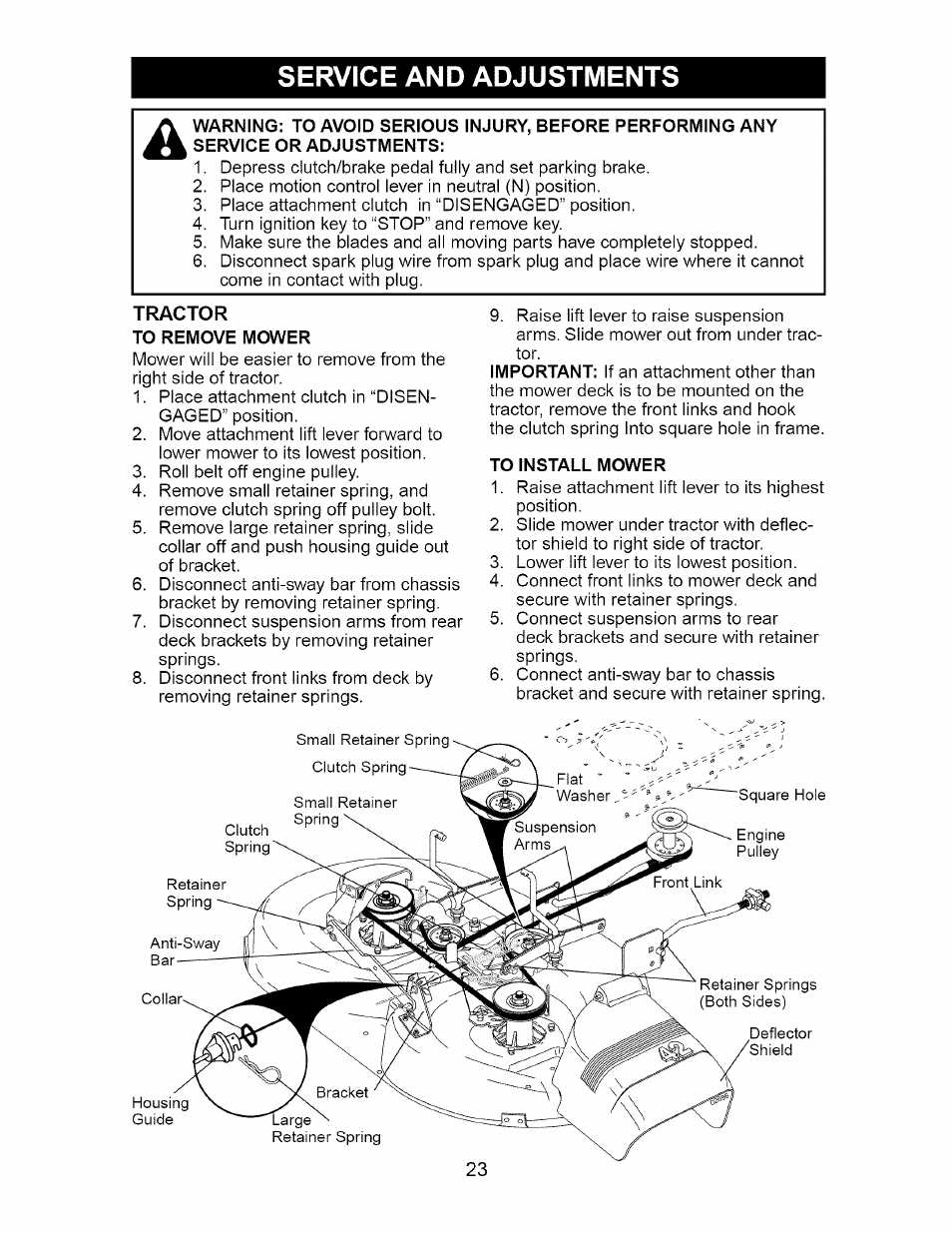

This section addresses frequent problems that users may encounter with their equipment and offers solutions to resolve them effectively. By following these guidelines, you can ensure smooth operation and minimize downtime.

Engine Won’t Start

If the engine fails to start, check the fuel level and ensure that the ignition switch is in the correct position. Additionally, inspect the battery connections for any corrosion or looseness. A faulty spark plug can also prevent starting, so consider replacing it if necessary.

Unusual Noises During Operation

Strange sounds may indicate mechanical issues. First, verify that all components are securely attached. Loose parts can create vibrations that lead to noise. If the sounds persist, check for signs of wear or damage in the drive belts and other moving parts, which may require replacement.