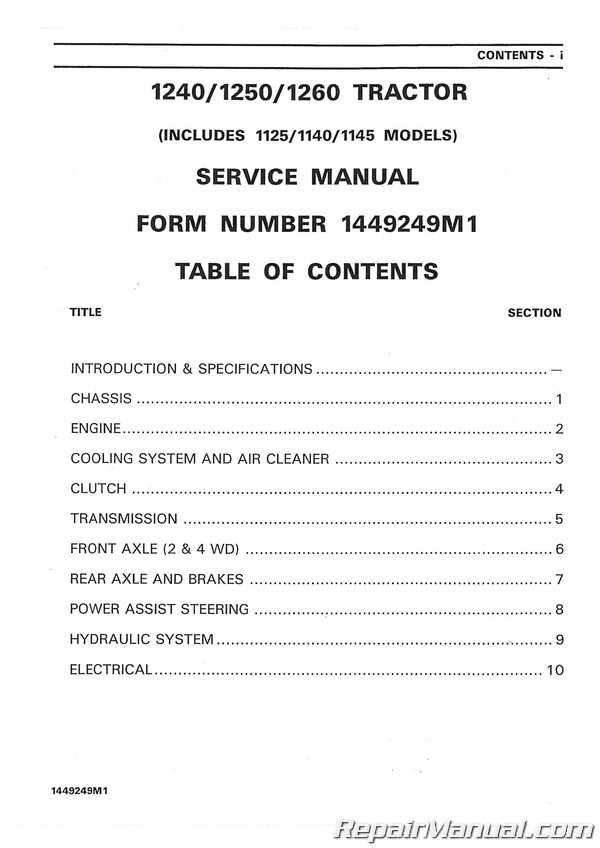

Understanding the key principles of equipment functionality is crucial for ensuring smooth and efficient use. This section provides an in-depth exploration of the operational features, settings, and important maintenance procedures to help users maximize performance. It serves as a practical resource for anyone looking to enhance their working experience with this versatile machine.

Throughout this guide, you will find essential instructions and best practices for adjusting, maintaining, and troubleshooting various systems. The goal is to empower users with the knowledge needed to operate the machinery safely and effectively, ensuring longevity and optimal performance under different conditions.

By following the tips and insights provided, users can improve both operational efficiency and the durability of their equipment, reducing the likelihood of issues arising during regular use. Whether you’re fine-tuning settings or performing routine maintenance, this guide offers valuable guidance every step of the way.

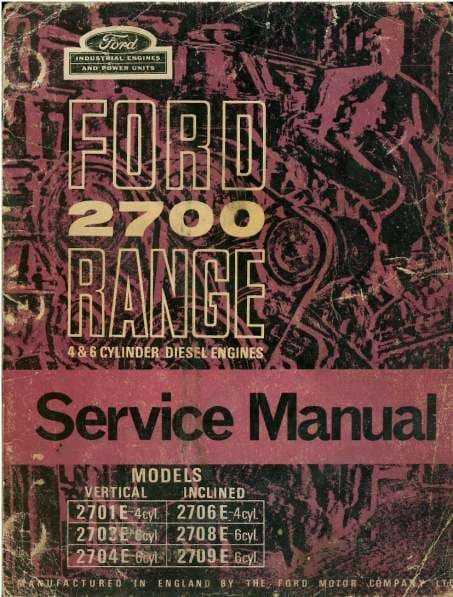

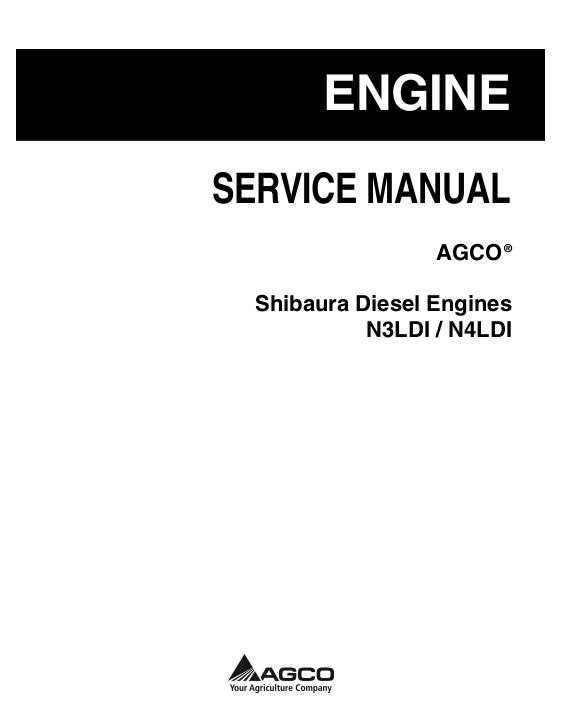

Comprehensive Overview of Massey Ferguson 2706E

This section provides a detailed exploration of a versatile agricultural vehicle designed for efficiency and reliability in various farming applications. Its structure, capabilities, and practical features make it a valuable tool for both large-scale and smaller operations. The machine’s robust build and powerful performance enable it to handle a range of tasks with ease, offering users enhanced productivity and ease of use.

Key Features and Capabilities

Engineered with precision, this model boasts an efficient engine, advanced hydraulics, and customizable options that cater to a variety of needs. Its adaptability to different implements and attachments ensures that users can switch between tasks seamlessly. The ergonomic controls and user-friendly dashboard further enhance the experience, making operation simple yet highly effective.

Performance in Diverse Conditions

Whether operating in challenging terrain or under heavy workloads, this model performs consistently, providing the necessary power and traction. It is also equipped with features that optimize fuel efficiency and reduce downtime, making it both an economical and environmentally friendly choice. These characteristics ensure that the vehicle meets the demands of modern farming with reliability and resilience.

Maintenance Guidelines and Safety Precautions

Regular upkeep and attention to safety are essential for ensuring the longevity and efficient performance of your equipment. Adopting a proactive approach to servicing not only extends the life of your machine but also minimizes potential hazards and breakdowns.

- Perform routine checks on fluid levels, including oil, coolant, and hydraulic fluids.

- Inspect and clean air filters frequently to prevent dust and debris buildup, which can reduce efficiency.

- Examine belts and hoses for signs of wear or cracks, and replace them when necessary.

- Lubricate moving parts regularly to prevent excessive friction and wear.

- Ensure all bolts and fasteners are securely tightened to avoid mechanical failure during operation.

Safety Precautions

Prioritizing safety is vital for both the operator and those around the equipment. Observing these precautions will help reduce the risk of accidents.

- Always turn off the engine and disconnect the power before performing any maintenance or adjustments.

- Wear appropriate protective gear, such as gloves, goggles, and sturdy footwear, when servicing the machine.

- Ensure the machine is on a level surface and properly supported before working beneath it.

- Keep the area around the machine clean and free of obstacles to avoid tripping hazards.

- Follow the recommended service intervals and replace any worn or damaged parts promptly.

By following these maintenance practices and safety guidelines, you can ensure reliable performance while reducing the risk of costly repairs or dangerous accidents.

Troubleshooting Common Operational Issues

Understanding and addressing common technical issues is essential for ensuring smooth operation and reducing downtime. In this section, we will explore typical challenges that may arise during use and provide straightforward solutions to keep your equipment running efficiently.

Engine Starting Problems

If the engine fails to start, several factors could be the cause. Begin by checking the fuel system, as insufficient fuel or a blocked filter can hinder proper ignition. Additionally, battery connections should be inspected for corrosion or looseness, which may prevent the starter from functioning.

- Check fuel levels and ensure the tank is properly filled.

- Inspect fuel lines and filters for blockages or leaks.

- Test battery voltage and clean terminals to ensure good electrical contact.

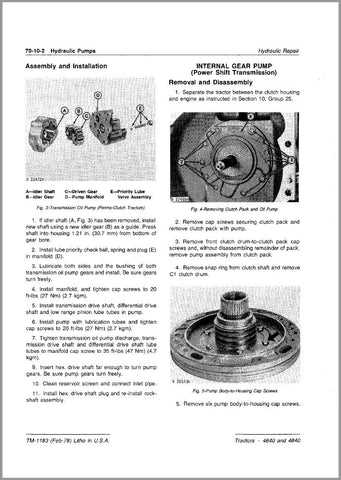

Hydraulic System Issues

Hydraulic system malfunctions often result in sluggish performance or failure to lift implements. The root of the problem may lie in fluid levels, contamination, or pressure settings. Ensuring regular maintenance of these components will minimize such occurrences.

- Check hydraulic fluid levels and top up if necessary.

- Inspect hydraulic hoses and connectors for leaks or damage.

- Ensure pressure settings are correctly adjusted according to specifications.