This section is designed to provide essential information for users of specific machinery, ensuring a comprehensive understanding of its features and functions. With a focus on maintenance, operation, and troubleshooting, users can maximize the performance and longevity of their equipment.

By familiarizing yourself with the intricacies of your machinery, you can enhance your experience and ensure optimal efficiency. This guide will cover various aspects, from routine upkeep to operational best practices, enabling you to handle the equipment confidently and effectively.

Whether you are a seasoned user or new to this type of machinery, this resource aims to equip you with the necessary knowledge to address common challenges. Dive in to discover valuable insights that will aid in making informed decisions and improving overall functionality.

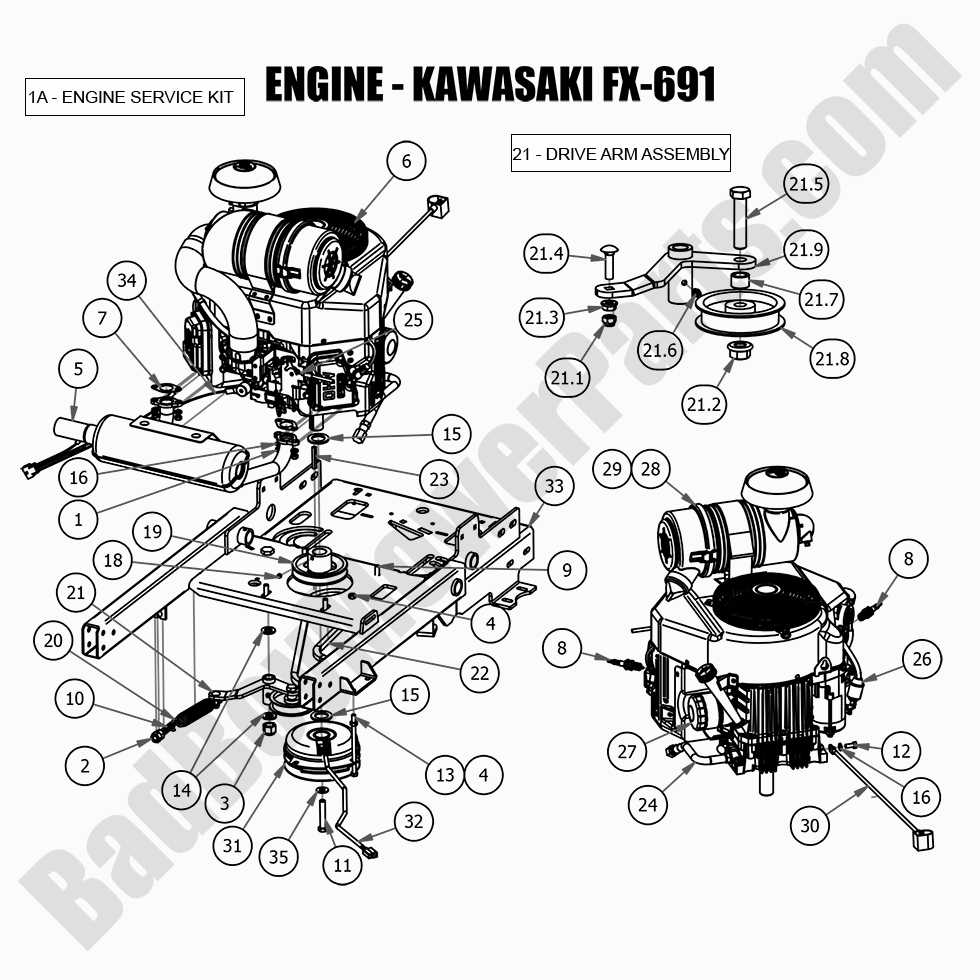

This section delves into the essential characteristics of a high-performance power unit, focusing on its design and functionality. The objective is to provide insights into the engine’s key features and operational principles that contribute to its efficiency and reliability in various applications.

Understanding the core components of the engine is crucial for maximizing its performance and ensuring longevity. The following table outlines the main elements that define the engine’s capabilities:

| Component | Description |

|---|---|

| Cylinder Configuration | Describes the arrangement of cylinders that impacts power delivery and smoothness. |

| Displacement | Indicates the total volume of all cylinders, influencing power output and efficiency. |

| Cooling System | Details the method of temperature regulation, essential for maintaining optimal operating conditions. |

| Fuel System | Describes the mechanism for fuel delivery, crucial for performance and efficiency. |

| Lubrication | Explains the process of minimizing friction and wear, vital for engine longevity. |

By comprehensively examining these aspects, users can gain a deeper understanding of how the power unit operates and how to maintain it effectively.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adhering to a structured maintenance routine can help prevent unexpected breakdowns and enhance overall functionality. This section outlines crucial practices that will help you achieve peak performance.

Routine Inspection and Cleaning

Frequent checks of all components are vital to identify any signs of wear or damage. Clean air filters and cooling systems regularly to ensure proper airflow and prevent overheating. Remove debris from around the unit to promote efficient operation and prolong its lifespan.

Lubrication and Fluid Levels

Keep all moving parts well-lubricated to minimize friction and wear. Regularly monitor and replenish essential fluids, such as oil and fuel, to maintain optimal performance. Consult the specific guidelines for the correct types and levels of fluids to ensure your equipment operates smoothly and efficiently.

Troubleshooting Common Issues

When operating machinery, encountering problems can be a common experience. Identifying and resolving these challenges is crucial for ensuring optimal performance. This section outlines typical complications and provides guidance on how to address them effectively.

Engine Performance Problems

- Engine Won’t Start:

- Check the fuel level and ensure it is sufficient.

- Inspect the battery for charge and connections.

- Look for any loose wires or connections.

- Rough Idling:

- Examine the air filter for dirt and blockage.

- Ensure the spark plug is clean and properly gapped.

- Adjust the carburetor settings if necessary.

Operational Concerns

- Unusual Noises:

- Listen for any rattling or grinding sounds.

- Check for loose parts or worn components.

- Lubricate moving parts as required.

- Overheating:

- Verify the cooling system is functioning properly.

- Inspect for blockages in the air intake or cooling fins.

- Ensure the oil level is adequate and the oil is clean.

Safe Operation and Usage Tips

Ensuring a secure and efficient experience while operating machinery is crucial for both user safety and equipment longevity. Following best practices can help prevent accidents and enhance performance, allowing for optimal use of the equipment.

Pre-Operation Checks

Before starting any operation, it is essential to conduct thorough inspections. Check for leaks, ensure all safety guards are in place, and confirm that the machinery is free from debris. Proper maintenance routines, such as changing fluids and replacing worn components, are vital to keeping the equipment in peak condition.

Safe Operating Procedures

Adhering to established operating procedures is key to minimizing risks. Always use appropriate personal protective equipment and maintain a clear workspace. Be mindful of your surroundings, particularly when maneuvering in tight spaces or working with attachments. Understanding the machinery’s capabilities and limitations will aid in effective and safe operation.