Maintaining and operating agricultural machinery efficiently is crucial for maximizing productivity and ensuring longevity. This section serves as a comprehensive resource aimed at providing essential information for users of specific models within the farming equipment category. Whether you are a seasoned operator or a newcomer, understanding your machine’s capabilities and features can significantly enhance your farming experience.

Here, you will find detailed insights into various operational aspects, including safety precautions, maintenance routines, and troubleshooting tips. Familiarizing yourself with these guidelines will not only improve your skills but also help in avoiding common pitfalls. Effective management of your equipment can lead to a more successful and sustainable farming operation.

By exploring the intricacies of your machine, you can harness its full potential. This guide aims to empower you with the knowledge necessary to navigate any challenges you may encounter. Embracing this information will ultimately contribute to a more efficient and productive agricultural practice.

Essential Maintenance for Kubota L225

Regular upkeep is crucial for ensuring optimal performance and longevity of your agricultural machinery. Proper maintenance not only enhances functionality but also prevents potential breakdowns and costly repairs. This section provides essential guidelines to help you maintain your equipment effectively.

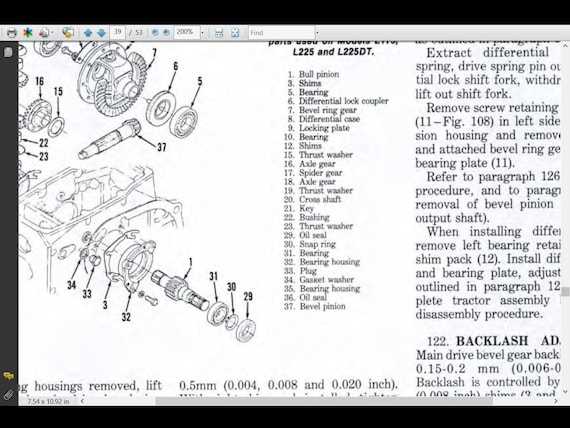

Routine Inspections

Conducting regular inspections is vital to identify any wear and tear. Check fluid levels, filters, and belts to ensure everything is in good condition. Inspecting tires for proper inflation and tread depth can also enhance safety and efficiency during operation.

Scheduled Servicing

Adhering to a servicing schedule is important for the overall health of your equipment. Follow the recommended intervals for oil changes, filter replacements, and other critical services. Utilizing high-quality lubricants and parts will further support the performance and reliability of your machine.

Understanding Features and Specifications

This section aims to provide insights into the essential characteristics and technical details of the compact tractor. Understanding these elements is crucial for potential users to assess its suitability for various agricultural tasks and maintenance needs.

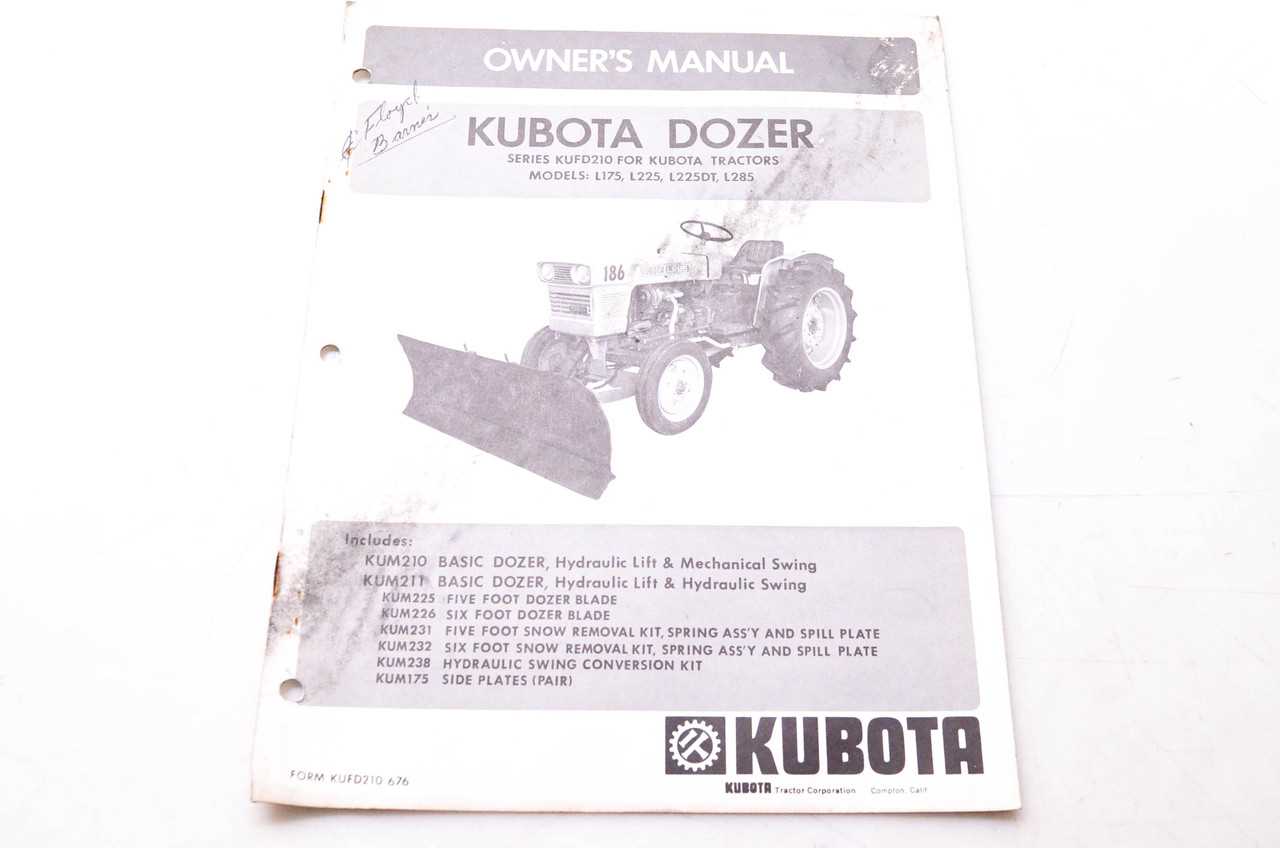

Compact tractors are designed with versatility in mind, offering a range of functionalities that enhance productivity. They typically include features such as powerful engines, efficient transmission systems, and ergonomic controls that facilitate ease of operation.

| Feature | Description |

|---|---|

| Engine Power | Typically features a robust engine that provides sufficient horsepower for various tasks, ensuring optimal performance in diverse conditions. |

| Transmission Type | Often equipped with a hydrostatic or gear-driven transmission, allowing smooth speed control and ease of use during operation. |

| Weight | Designed to be compact yet sturdy, providing stability and balance when operating attachments or performing heavy-duty tasks. |

| Attachment Compatibility | Compatible with a variety of implements such as loaders, backhoes, and mowers, enhancing its functionality for different applications. |

| Fuel Efficiency | Engineered for economical fuel consumption, ensuring longer operation times and reduced running costs for users. |

By familiarizing oneself with these attributes, users can make informed decisions regarding the performance capabilities and potential applications of this versatile machine.

Operating Guidelines for Efficiency

To maximize performance and ensure longevity in equipment, following certain operational practices is essential. Implementing these strategies will not only enhance productivity but also contribute to fuel savings and reduced wear and tear on components.

Regular Maintenance Checks

Conducting frequent inspections is vital for identifying potential issues before they escalate. Focus on the following areas:

- Engine oil levels and quality

- Air and fuel filter conditions

- Hydraulic fluid levels

- Tire pressure and tread wear

- Belts and hoses for signs of wear

Efficient Operating Techniques

Adopting best practices while operating machinery can significantly enhance efficiency:

- Plan tasks to minimize unnecessary movement.

- Utilize appropriate attachments for specific jobs.

- Monitor load levels to prevent overloading.

- Engage in smooth acceleration and deceleration.

- Take advantage of the machine’s optimal RPM range.

By integrating these practices into daily operations, users can achieve optimal performance while extending the lifespan of their equipment.